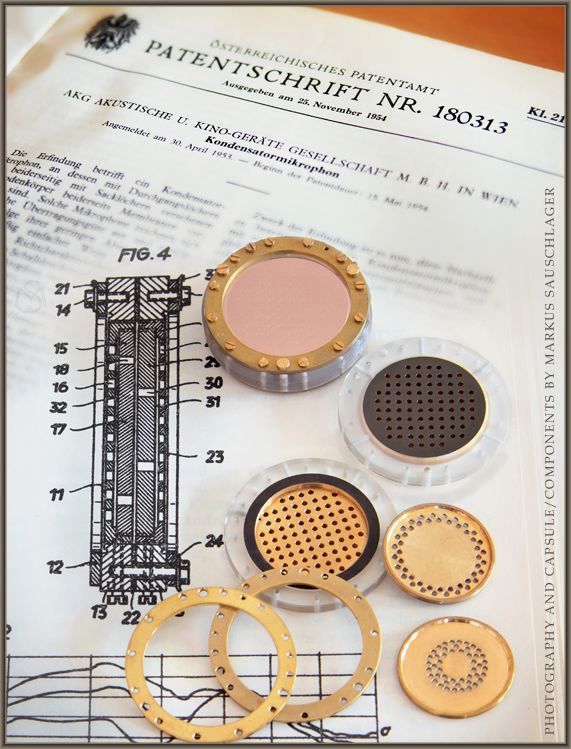

Patent AKG CK12 brass capsule

Pictured is the original, actual patent of the famous "brass CK12" condenser microphone capsule by AKG (Akustische und Kinogeräte Ges.m.b.H)

It is still held at the Austrian Patent Office in Vienna.

It shows a cross-section drawing of the earliest version of the brass CK12, featuring a larger diaphragm diameter of 26mm. That soon was changed to 25mm.

The CK12 was developed by AKG´s Konrad Wolf to be used in the C12 tube microphone in 1952/53. The C12 was the most innovative condenser microphone of it´s time. Also one of the most expensive.

To the present day it is the most complex acoustical/mechanical design among large diaphragm condenser transducers. Building the CK12 brass capsule demands extraordinary precision and dedicated manufacturing techniques. Because of the effort required this design was at first rejected by AKG´s head of manufacturing. Luckily Mr.Wolf successfully insisted on his construction remaining unchanged for serial production. The challenging build process was rewarded with unprecedented sound quality.

Being AKG´s only large diaphragm capsule this original construction was used in all AKG-made LDC mics until the late 1970´s. The last regular model featuring the CK12 brass capsule was the C414EB, a very reasonable priced mic compared to the old C12 tube microphone. The extraordinary high production costs of the brass CK12 didn´t make sense here anymore and made this mic uneconomic. Instead of cutting corners and simplifying the old capsule construction (e.g. by changing the precision screw joints of the backplate´s components to glued joints - like in today´s aftermarket CK12-replicas) AKG decided to remodel the CK12 entirely and make use of mass production techniques (such as injection molding) in order to stay competitive. The resulting CK12 incarnation is the infamous "Nylon CK12". The injection molded body of this capsule is made from white polyamide (Nylon). It´s often confused with Teflon. That´s why many people refer to it as "Teflon CK12".

Despite the very different construction of the Nylon CK12 capsule the basic acoustical working principle as outlined in the old patent remains unchanged. A clear benefit of the Nylon-CK12 is it´s high humidity-resilience.

However, the no-compromise construction of the original brass CK12 produces a unique sonic signature that´s usually preferred by most audio professionals.

The pictured capsule and components were manufactured in 2012 in Vienna by Markus Sauschlager, using the traditional techniques. The project impressively proved that the original design is way too expensive to produce in today's time and age so this reissue has been discontinued.

In spring 2019 a totally newly developed incarnation of the CK12 was introduced to the market by "Austrian Audio GmbH", called the "CKR12". The new CKR12 capsule was designed around the acoustical properties of the brass CK12, but in a modern enclosure and construction that is suitable for commercial serial production today. Made in Vienna, it features a unique ceramic enclosure with integrated elastic suspension that houses the capsule´s diaphragms, backplates and air friction element. It is certainly the most innovative new product based on the original CK12 patent. So far it is offered in the Austrian Audio OC818 and OC18 recording microphones.

Find more information about the classic AKG brass CK12 here:

AKG CK12 (ck12 brass capsule) general info

Markus Sauschlager

AKG C12A tube condenser microphone

Markus Sauschlager

AKG C12 - Siemens SM204/23

Markus Sauschlager

AKG C414

Markus Sauschlager

AKG C414EB Condenser microphone

Markus Sauschlager

Austrian made C12 reissue 2018

Markus Sauschlager

Link to CK12 Patent:

https://depatisnet.dpma.de/DepatisNet/depatisnet?window=1&space=menu&content=treffer&action=pdf&docid=AT000000180313B

(this is a scanned photocopy of the complete original AKG CK12 brass capsule patent as shown in my picture)

https://at.linkedin.com/in/sauschlager

Commercially produced aftermarket replica capsules in the style of the AKG Brass-CK12 include the Tim Campbell CT12 - Denmark, Eric Heiserman HK12 - USA, Beesneez CK12 - Australia

.

Commenti 0

Cancella commento

Eliminare commento e risposte